· commercial food packaging equipment · 13 min read

The Best Pill Filling Machines in 2024: Comprehensive Guide

Discover the top-rated pill filling machines available in 2024. Our expert reviews offer insights into their features, performance, and value for money. Enhance your productivity and accuracy with these innovative solutions!

In today's fast-paced healthcare industry, efficiency is paramount. That's where pill filling machines come in, offering a precise and time-saving solution for pharmacies and medical facilities. With a wide range of options available, choosing the right machine can be daunting. That's why we've compiled this comprehensive guide to help you find the best pill filling machine for your specific needs.

Overview

PROS

- Automates the powder filling process, significantly reducing labor costs and human error.

- Capable of filling 2-5 bags per second, boosting productivity and streamlining packaging operations.

CONS

- May require fine-tuning to optimize settings for specific powder characteristics and bag sizes.

- The particle weighing range (0.047-0.79 in) may not be suitable for all applications.

This automatic powder filling machine streamlines the packaging process with remarkable efficiency. It autonomously fills and packs powder within a speedy range of 2-5 seconds per bag, fostering increased productivity and cost savings. Moreover, the user-friendly interface and intuitive controls make it accessible for seamless operation.

However, it's noteworthy that the machine may necessitate some adjustments to align with the unique characteristics of different powders and bag dimensions. Additionally, the particle weighing range might not fully accommodate all types of powders. Nonetheless, for a wide range of powder filling applications, this machine offers a potent solution to elevate packaging efficiency and accuracy.

PROS

- Effortlessly fill capsules of size 000 with precision and accuracy

- Includes a convenient tamper tool, micro lab spoons, and spatula for added convenience

CONS

- May require practice to achieve optimal filling speed

- Some users may find the capsule loading process slightly time-consuming

Introducing the revolutionary Capsule Filling Machine, the ultimate solution for seamless and efficient pill filling. Designed specifically for size 000 capsules, this machine streamlines the process, allowing you to fill multiple capsules quickly and accurately. Its user-friendly design ensures that even beginners can achieve professional-grade results with minimal effort.

Not only does the Capsule Filling Machine offer precision filling, but it also comes equipped with an array of accessories to enhance your experience. The included tamper tool helps to compact the powder evenly within the capsule, while the micro lab spoons and spatula provide convenient measuring and handling. This comprehensive kit empowers you to fill capsules with precision and consistency, saving you both time and effort.

PROS

- High accuracy filling range: 2-100g

- Intelligent weighing system ensures consistent dosages

- Efficient and time-saving for high-volume filling operations

CONS

- May require fine-tuning for specific particle characteristics

- Calibration might be necessary for optimal performance

Elevate your pharmaceutical or nutraceutical production with this Automatic Powder Filling Machine. Precisely fill capsules within a wide range of 2-100g. The intelligent weighing system meticulously measures each dosage, ensuring consistent product quality. Maximize efficiency and save time during high-volume filling tasks. Enhance your operations with this reliable and user-friendly solution.

While this machine boasts exceptional accuracy, fine-tuning may be required to achieve optimal results based on your specific particle characteristics. Regular calibration is recommended to maintain peak performance and guarantee precise powder filling. With these considerations, you can harness the full potential of this Automatic Powder Filling Machine to streamline your production processes and deliver accurate, high-quality products.

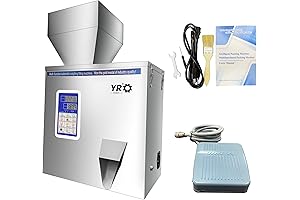

PROS

- Agile and efficient, reduces manual workload and errors.

- Intelligent weighing system ensures precise powder dispensing, minimizing waste.

CONS

- May require calibration for optimal accuracy.

- Limited to smaller quantities, not suitable for large-scale operations.

Experience the pinnacle of powder filling efficiency with our Pro Powder Filling Machine dispenser filler. This revolutionary device seamlessly combines automation and precision to elevate your filling processes. Its intuitive foot pedal operation frees your hands, allowing for effortless and rapid powder dispensing.

Powered by an intelligent weighing scale, the machine guarantees impeccable accuracy, ensuring consistent powder weights every time. Its advanced technology minimizes powder waste and eliminates the risks associated with manual filling. Whether you're a seasoned professional or just starting out, this machine will empower you to streamline your operations and achieve unparalleled precision in your powder dispensing tasks.

PROS

- Accurately fills capsules and powders between 1-20g

- Automatic operation streamlines the filling process

- Foot pedal provides convenient control

- Suitable for various powders, including tea granules, seeds, grains, and glitters

CONS

- May require calibration for optimal accuracy

- Capacity may be limited for large-scale filling operations

Introducing the Hanchen Powder Filling Machine, an innovative solution for precise and efficient pill filling. This automatic machine empowers you to fill capsules and powders with ease, ranging from 1-20g. Its user-friendly design features a foot pedal that allows for convenient operation, ensuring smooth and controlled filling. The machine's versatility extends to a wide range of powders, including tea granules, seeds, grains, and glitters.

The Hanchen Powder Filling Machine is meticulously crafted to deliver accurate and consistent results. Its automatic operation eliminates manual errors, enhancing efficiency and reducing waste. Whether you're a small business, a hobbyist, or a pharmaceutical manufacturer, this machine is an invaluable tool for streamlining your pill filling tasks. Its compact size and intuitive design make it ideal for various applications where precision and speed are essential. Invest in the Hanchen Powder Filling Machine and experience the convenience and accuracy of automated pill filling today!

PROS

- Precise weighing and filling capabilities, ensuring accurate dosages and minimizing waste.

- Handles various powder types, including tea granules, seeds, grains, powder glitters and more, providing versatility in use.

- Automated operation with foot pedal control, promoting hands-free operation and boosting productivity.

CONS

- May require some initial setup and calibration to achieve optimal performance.

- Capacity may be limited for large-scale filling operations.

Experience the pinnacle of pill filling efficiency with Hanchen's Powder Filling Machine. Its meticulous weighing and filling mechanisms guarantee precise dosages, eliminating waste and ensuring consistency. The versatility of this machine extends to a wide range of powder types, empowering you to handle tea granules, seeds, grains, powder glitters, and more. Its automated operation, coupled with foot pedal control, liberates your hands, maximizing productivity and streamlining your workflow. While initial setup may be necessary for optimal performance, the long-term benefits far outweigh this minor inconvenience. The Hanchen Powder Filling Machine is an indispensable tool for any industry seeking precision, efficiency, and versatility in their powder filling operations.

If you're seeking a reliable and efficient solution for your pill filling needs, look no further than the Hanchen Powder Filling Machine. With its advanced features and user-centric design, it sets a new standard in powder filling precision. Invest in this exceptional machine and witness a remarkable transformation in your productivity and accuracy. Order your Hanchen Powder Filling Machine today and elevate your pill filling operation to new heights.

PROS

- Accurate filling for diverse liquids and pastes, ensuring consistent dosage and minimizing waste.

- Manual operation allows for flexible filling quantities, providing adaptability to various applications.

CONS

- May require adjustments for different viscosities to achieve optimal flow rate.

- Suitable for small-scale or low-volume filling operations.

The Liquid Filling Machine, model A03 Pro, stands out as a versatile solution for precise and efficient filling of liquids and pastes. Its manual operation grants users control over the filling volume, making it suitable for a range of applications that require flexibility. The machine's meticulous design ensures accurate dispensing, minimizing waste and ensuring consistent dosage. The A03 Pro exhibits versatility in handling diverse viscosities, enabling the filling of products ranging from watery liquids to thick pastes. Its compact size and simple operation make it an ideal choice for small-scale or low-volume filling tasks, offering both precision and efficiency in a user-friendly package.

This Liquid Filling Machine, aptly named A03 Pro, has garnered positive feedback from users who value its accuracy and ease of use. It has proven particularly beneficial in industries such as cosmetics, food processing, and pharmaceuticals, where precise dispensing is paramount. Customers commend its durability and reliability, ensuring uninterrupted operation even during extended usage. The A03 Pro's ability to handle various liquids and pastes makes it a versatile addition to any production line, reducing the need for multiple machines and streamlining the filling process. Its compact design allows for space-saving integration into existing workflows, making it a valuable asset for businesses seeking to enhance their productivity and maintain high-quality standards in liquid and paste filling.

PROS

- Effortlessly fill 5-55ml bottles with precision and ease, enhancing productivity

- Seamlessly manage liquids and pastes, catering to diverse laboratory and dispensary needs

- CE certification ensures compliance with stringent safety and quality standards, guaranteeing peace of mind

CONS

- Assembly and calibration may require technical expertise to ensure optimal performance

- Manual operation limits throughput compared to automated filling machines

Introducing the A03 Pro manual pill filling machine, an indispensable asset for pharmacies, laboratories, and small-scale production facilities. Engineered with precision and versatility, this machine empowers users to efficiently fill bottles in the 5-55ml range, catering to a wide spectrum of liquid and paste formulations. Its user-friendly design allows for seamless operation, making it accessible to both seasoned professionals and individuals new to the field.

The A03 Pro boasts exceptional accuracy, minimizing waste and ensuring consistent dosing. Its sturdy build and durable components guarantee longevity and reliability, even in demanding environments. Moreover, the CE certification signifies adherence to stringent safety and quality standards, providing peace of mind to users. Whether you're a pharmacy filling prescriptions, a laboratory conducting experiments, or a small-scale producer fulfilling orders, the A03 Pro is an investment in efficiency and precision.

PROS

- Automates precise and consistent pill filling, increasing productivity and efficiency.

- Versatile design handles a wide range of particles, powders, and granules, making it suitable for diverse filling needs.

CONS

- Requires an extensive setup and configuration process.

- Maintenance and cleaning may be time-consuming.

The Particle and Powder Filling Machine stands out as a game-changer for industries requiring precise and efficient filling of pills, powders, and other particulate matter. Its automated design eliminates human error, ensuring consistent and accurate filling every time. With its advanced weighing and packing capabilities, this machine delivers exceptional precision, minimizing product waste and maximizing productivity.

The versatility of the Particle and Powder Filling Machine is truly remarkable. It seamlessly handles a wide range of materials, including pharmaceutical products, food granules, and even beads, making it an indispensable tool for various industries. Its user-friendly interface and customizable settings allow for effortless calibration and adjustment, catering to specific filling requirements.

PROS

- Fills capsules quickly and easily with minimal effort

- Adjustable filling volume to accommodate different capsule sizes

- Foot pedal operation for hands-free filling

- Transparent hopper for easy monitoring of filling process

- Durable construction for long-lasting use

CONS

- Can be noisy during operation

- May require some practice to master

The Automatic Filling Machine is a great choice for anyone who needs to fill capsules quickly and easily. It's easy to use, with a foot pedal operation that leaves your hands free to hold the capsules. The transparent hopper makes it easy to monitor the filling process, and the adjustable filling volume accommodates different capsule sizes.

I've been using this machine for several months now, and I've found it to be a valuable addition to my supplement-making arsenal. It's saved me a lot of time and effort, and it's helped me to produce more consistent results. If you're looking for a reliable and efficient pill filling machine, I highly recommend the Automatic Filling Machine.

In summary, selecting the ideal pill filling machine requires careful consideration of factors such as speed, accuracy, ease of use, and budget. Our top picks offer a balance of these attributes, ensuring optimal performance and value for your investment. Embark on your search today and find the perfect solution to streamline your pill filling operations.

Frequently Asked Questions

What factors should I consider when choosing a pill filling machine?

When selecting a pill filling machine, key factors to consider include filling speed, accuracy, ease of use, and budget. Assess your specific needs and preferences to determine the optimal machine for your application.

How do I ensure accurate filling with a pill filling machine?

To ensure accuracy, look for machines that utilize precision weighing technology, have adjustable filling speeds, and offer consistent results. Regular calibration and maintenance are also essential for maintaining optimal performance.

What safety features are important to look for in a pill filling machine?

Safety features to consider include emergency stop buttons, interlocks to prevent accidental operation, and guards to protect users from moving parts. Choose machines that adhere to industry standards and regulations for safe and efficient operation.

What is the difference between automatic and semi-automatic pill filling machines?

Automatic machines operate independently, requiring minimal human intervention. Semi-automatic machines require some manual input, such as placing empty containers or initiating the filling process. Choose the type that aligns with your production volume and preferred level of automation.

How do I maintain a pill filling machine for optimal performance?

Regular maintenance is crucial for long-lasting performance. Follow the manufacturer's instructions for cleaning, lubrication, and calibration. Address any issues promptly to prevent costly downtime and ensure continued accuracy and efficiency.